The Application and Selection of Superhard Materials in Wire Drawing Dies

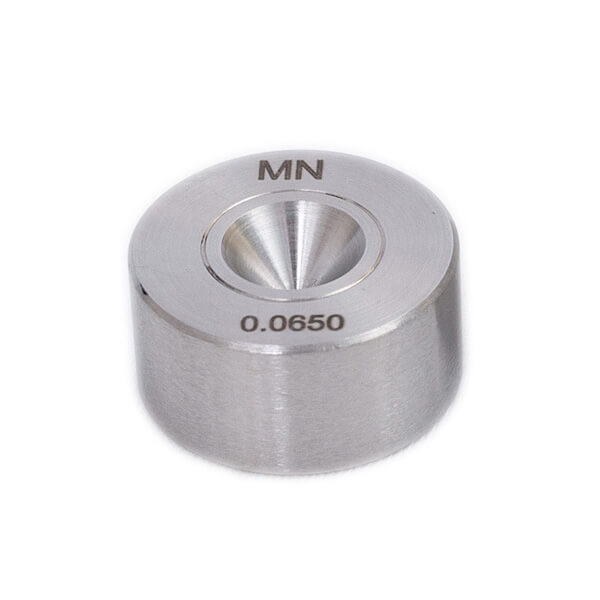

Superhard materials are widely used in various industrial productions, especially in the manufacturing of wire drawing dies. The quality of wire drawing dies directly affects the surface quality, dimensional accuracy, and production efficiency of the drawn wires. For different types of wires, such as copper wire, aluminum wire, steel wire, gold wire, and silver wire, selecting the appropriate die material is particularly crucial. This article will introduce superhard materials and their application in wire drawing dies, while discussing how to choose die materials for different wire types, and highlight the advantages of the wire drawing dies produced by Zhengzhou Main Machinery Equipment Co., Ltd. (MN Company).

1. Overview of Superhard Materials

Superhard materials generally refer to materials with extremely high hardness, such as natural diamond, synthetic diamond, and carbide. These materials share the characteristics of excellent wear resistance, high compressive strength, and extreme hardness, making them ideal for high-load, high-wear wire drawing processes.

- Natural Diamond: The hardest material with a low friction coefficient, suitable for fine processing.

- Polycrystalline Diamond (PCD): Cheaper and more stable compared to natural diamond, suitable for large-scale industrial production.

- Carbide (Tungsten Carbide): Lower hardness than diamond materials but offers excellent wear resistance, suitable for drawing general wire types.

2. Copper Wire Die Material Selection

Copper wire is relatively soft and is often used in the production of cables and electrical wires. Due to its ductility and oxidation resistance, the drawing process does not excessively wear the die.

- Recommended Die Material: Natural Diamond or Polycrystalline Diamond (PCD).

- Reason: Diamond dies offer excellent wear resistance and can maintain the surface smoothness of the copper wire. The low friction coefficient during drawing also helps increase production efficiency.

3. Aluminum Wire Die Material Selection

Aluminum wire, similar to copper wire, has lower strength but tends to form an oxide layer during the drawing process, requiring a more wear-resistant die to ensure surface quality.

- Recommended Die Material: Polycrystalline Diamond (PCD) or Carbide.

- Reason: Aluminum wire is highly ductile, and the drawing process generates high temperatures. PCD dies offer excellent thermal conductivity, reducing the impact of high temperatures on the die, and have better wear resistance than carbide.

4. Steel Wire Die Material Selection

Steel wire drawing is much more complex than copper and aluminum wires due to the higher hardness of steel, which causes significant die wear.

- Recommended Die Material: Carbide or CVD Diamond Coated Dies.

- Reason: The drawing of steel wire involves severe die wear. Carbide dies provide strong impact resistance and wear resistance, while CVD diamond-coated dies deliver higher surface smoothness and wear resistance, suitable for high-precision steel wire drawing.

5. Gold Wire Die Material Selection

Gold wire is mainly used in precision electronic components and jewelry. Its ductility is excellent, but due to the high cost of materials, the die precision must be extremely high.

- Recommended Die Material: Natural Diamond or High-Precision Polycrystalline Diamond (PCD).

- Reason: Gold wire requires an extremely high level of surface smoothness and dimensional precision. The extreme hardness and low friction coefficient of natural diamond make it the ideal choice for gold wire drawing.

6. Silver Wire Die Material Selection

Silver wire is similar to gold wire but slightly harder, thus requiring a slightly stronger die material.

- Recommended Die Material: Polycrystalline Diamond (PCD) or Natural Diamond.

- Reason: Silver wire is highly ductile, and PCD dies can ensure durability while maintaining a high surface smoothness.

7. Advantages of Wire Drawing Dies Produced by Zhengzhou Main Machinery Equipment Co., Ltd.

Zhengzhou Main Machinery Equipment Co., Ltd. (MN Company), a professional manufacturer of wire drawing dies, leverages rich experience and advanced manufacturing processes to provide high-quality wire drawing die products. Especially in the production of superhard material wire drawing dies, the company offers the following distinct advantages:

- High-Quality Raw Materials: The company uses high-purity natural diamonds and advanced polycrystalline diamonds (PCD), ensuring the highest hardness and wear resistance in their dies, which can maintain superior performance over extended periods.

- Precision Manufacturing: The company employs advanced CNC machines and laser technology to ensure that every die achieves micron-level accuracy, making them particularly suitable for high-precision wire drawing, such as for gold and silver wires.

- Custom Solutions: Based on customer requirements, the company offers tailored die solutions for different wire types (such as copper, aluminum, and steel), ensuring optimal drawing results and improving production efficiency.

- Cost-Effective: Compared to international brands, MN Company’s wire drawing dies maintain high quality while offering competitive prices, making them suitable for large-scale production.

- Durability: Due to the use of superior superhard materials and advanced techniques, MN Company’s dies perform excellently in high-load production environments, significantly extending die life, reducing replacement frequency, and lowering production costs.

| Wire Type | Recommended Die Material | Reason | Application |

| Copper Wire | Natural Diamond / Polycrystalline Diamond (PCD | Excellent wear resistance, low friction, high surface smoothness | Cable and wire production |

| Aluminum Wire | Polycrystalline Diamond (PCD) / Carbide | High ductility, heat-resistant, good thermal conductivity | Power transmission, construction wiring |

| Steel Wire | Carbide / CVD Diamond Coating | High hardness, strong impact resistance, suitable for high-precision wire drawing | Construction, engineering wire |

| Gold Wire | Natural Diamond / High-Precision PCD | Extremely high surface smoothness and precision requirements | Precision electronics, jewelry making |

| Silver Wire | Polycrystalline Diamond (PCD) / Natural Diamond | Good ductility, maintains surface smoothness | Jewelry, electrical connectors |

Conclusion

In the wire drawing process, different wire types require different die materials due to their unique material properties. Proper die material selection not only improves production efficiency but also extends die life and reduces costs. Zhengzhou Main Machinery Equipment Co., Ltd. stands out as an ideal partner for wire production companies, providing superior wire drawing die solutions with high-quality superhard materials, precision manufacturing, and strong customization capabilities.