High Pressure High Temperature (HPHT) or Chemical Vapor Deposition (CVD) technologies. Below is a detailed production process:

1. High Pressure High Temperature (HPHT) Method

This method mimics the conditions under which diamonds are formed in the Earth’s interior by subjecting a carbon source and metal catalysts (such as iron, cobalt, nickel, etc.) to extremely high temperatures and pressures to synthesize polycrystalline diamonds.

- Process:

- Mix diamond particles (usually small single crystal diamond particles) with metal catalysts.

- Heat the mixture at temperatures of several thousand degrees Celsius and pressures of several hundred thousand pascals, causing the diamond particles to recrystallize under the influence of the catalysts.

- During this process, the diamond particles will aggregate together, forming a solid polycrystalline diamond block.

- Features: This method produces polycrystalline diamonds with high strength, hardness, and wear resistance, which are widely used in cutting tools, abrasives, and drill bits for industrial applications.

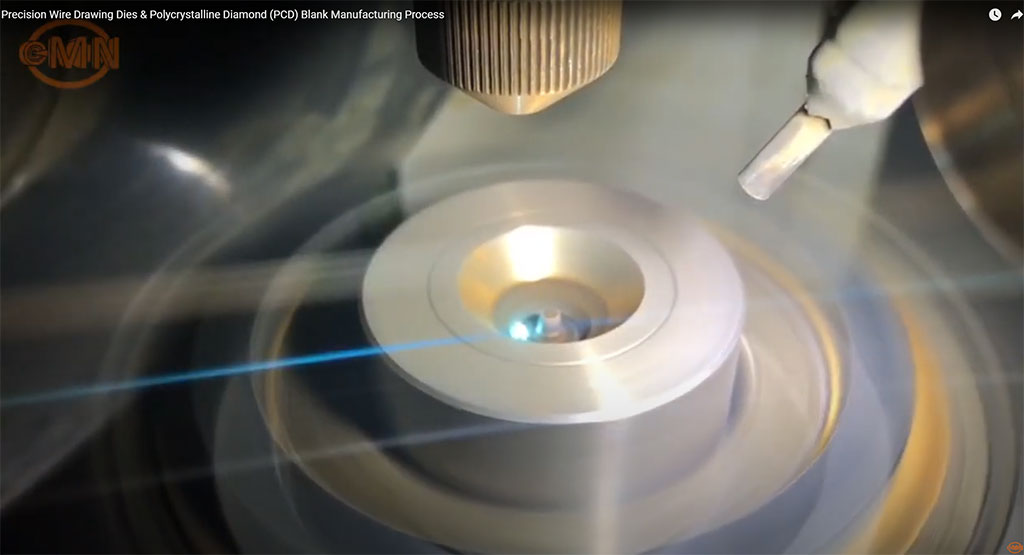

2. Chemical Vapor Deposition (CVD) Method

The CVD method synthesizes polycrystalline diamond by providing a carbon source (typically methane) in a gas phase and using electric fields or microwave energy to decompose the gas, depositing diamond layers on a substrate and gradually forming a polycrystalline structure.

- Process:

- In a vacuum chamber, generate a carbon source from gases (such as methane and hydrogen) under low pressure.

- Use high temperatures (around 700-1000°C) and an excited electric field to decompose the gases, allowing carbon atoms to deposit onto the substrate surface.

- Through multiple deposition cycles, a polycrystalline diamond material is gradually formed.

- Features: The CVD method allows for more precise control over the thickness and structure of the diamond layers, making it widely used for thin-film diamond manufacturing and micro-tools.

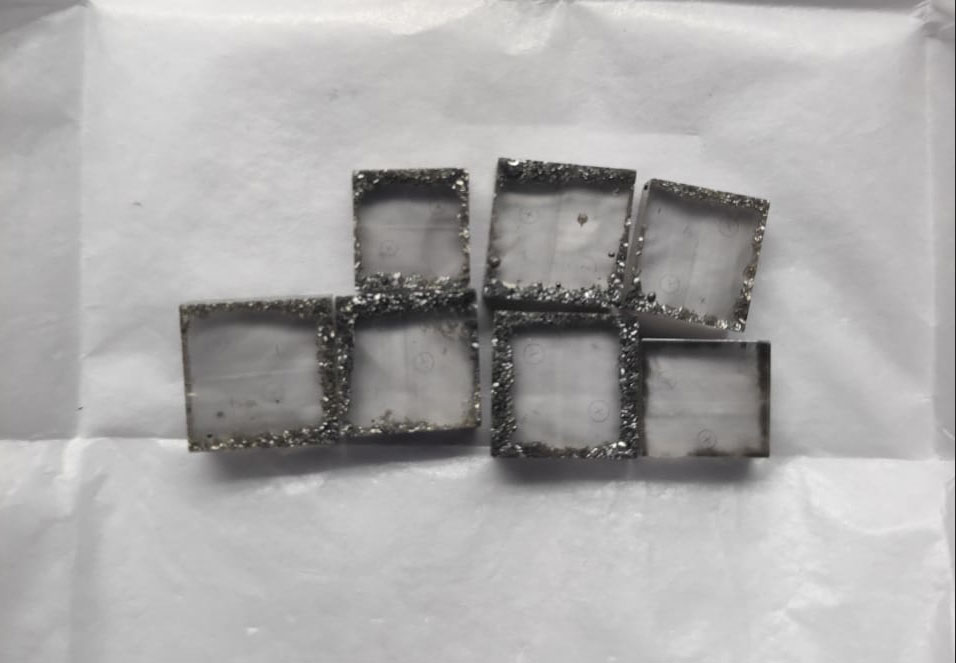

3. Traditional Polycrystalline Diamond Production

Some polycrystalline diamond materials are produced by pressing diamond particles with a bonding metal (such as cobalt) and sintering them at high temperatures. These methods are typically used for industrial-scale production, primarily for manufacturing diamond tools, cutting tools, and other equipment.

4. Diamond Particles Sources

The raw materials for producing polycrystalline diamond typically come from:

- Natural Diamond Particles: Sometimes small natural diamond particles are used as raw material.

- Synthetic Single Crystal Diamond Particles: Single crystal diamonds are first synthesized using HPHT or CVD methods and then used as raw material.

Conclusion:

The production of polycrystalline diamonds relies on advanced high pressure high temperature (HPHT) or chemical vapor deposition (CVD) technologies. These methods allow multiple diamond grains to aggregate, forming a material with exceptionally high hardness and wear resistance, making it widely used in tools, abrasives, and cutting equipment.