- Polycrystalline Diamond wire drawing dies with PCD blanks wire die can be used for ferrous and non-ferrous wire drawing applications and for virtually any type of wet and dry wire drawing process.

- Sizes are available for drawing applications ranging from large drawn rod to ultra-fine wire.

- This size range includes, but is not limited to 0.030 to 22 mm.

Polycrystalline Diamond Wire Drawing Dies (PCD)

Polycrystalline diamonds are man-made sintered diamonds. Diamond wire dies with PCD blanks can be used for ferrous and non-ferrous wire drawing applications and for virtually any type of wet and dry wire drawing process. Sizes are available for drawing applications ranging from large drawn rod to ultra-fine wire. This size range includes, but is not limited to 0.030 to 22 mm.

MN Die supply 4 different kinds of PCD dies to draw different materials, best applications by keeping high quality as well as low cost possible.

We supply semifinished dies and finished dies.

PCD dies are made for all kinds of applications in drawing, compacting, stranding, tube and bar calibrating.

Applications and PCD blanks grain

| 1 Micron | 3 Micron | 5 Micron | 12 Micron | 25 Micron | 50 Micron |

|---|---|---|---|---|---|

| Better surface quality | Better surface quality | Better surface quality | Longer die life | Longer die life | Longer die life |

| Tungsten | Tungsten | Tungsten | |||

| Brass covered steel | Brass covered steel | Brass covered steel | Brass covered steel | ||

| Speciaty metal | Speciaty metal | Speciaty metal | Speciaty metal | ||

| Low carbide steel | Low carbide steel | Low carbide steel | |||

| Welding wire | Welding wire | Welding wire | |||

| Stainless steel | Stainless steel | Stainless steel | |||

| Copper | Copper | ||||

| Aluminium | Aluminium |

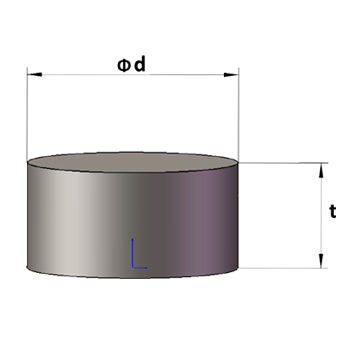

| ADDMA | Blanks Diamond Size d(mm) | Blanks Diamond Size t(mm) | Soft Wire Max New Hole Diametre(mm) | Soft Wire Max Recut Hole Diametre(mm) | Hard Wire Max New Hole Diametre(mm) | Hard Wire Max Recut Hole Diametre(mm) | Grain Size 1μm | Grain Size 3μm | Grain Size 5μm | Grain Size 12μm | Grain Size 25μm | Grain Size 50μm | Case Size(mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D6 | 2.5 | 1.0 | 0.5 | 1.0 | 0.4 | 0.7 | ◎ | ◎ | ◎ | ◎ | 25*8 | ||

| D12 | 3.2 | 1.5 | 1.0 | 1.4 | 0.7 | 1.0 | ◎ | ◎ | ◎ | ◎ | 25*10 | ||

| D15 | 5.2 | 2.5 | 1.5 | 2.2 | 1.1 | 2.0 | ◎ | ◎ | ◎ | ◎ | 28*10 | ||

| D18 | 5.2 | 3.5 | 2.0 | 2.8 | 1.4 | ◎ | ◎ | ◎ | ◎ | 28*12 |

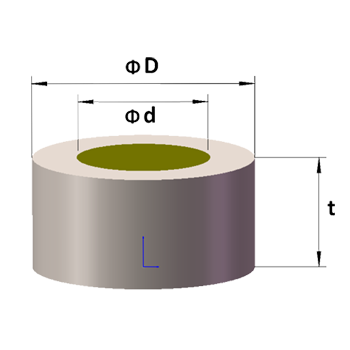

| ADDMA | Blanks Diamond Size D(mm) | Blanks Diamond Size d(mm) | Blanks Diamond Size t(mm) | Soft Wire Max New Hole Diametre(mm) | Soft Wire Max Recut Hole Diametre(mm) | Hard Wire Max New Hole Diametre(mm) | Hard Wire Max Recut Hole Diametre(mm) | Grain Size 1μm | Grain Size 3μm | Grain Size 5μm | Grain Size 12μm | Grain Size 25μm | Grain Size 50μm | Case Size(mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D12 | 4.00 | 1.5 | 1.5 | 0.8 | 1.0 | 0.6 | 0.7 | ◎ | ◎ | ◎ | ◎ | ◎ | 25*10 | |

| D15 | 8.12 | 4.0 | 2.3 | 1.8 | 2.2 | 1.3 | 1.5 | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | 28*10 |

| D18 | 8.12 | 4.0 | 2.9 | 2.3 | 2.4 | 1.6 | 1.7 | ◎ | ◎ | ◎ | ◎ | ◎ | ◎ | 28*12 |

| D21 | 13.65 | 7.0 | 4.0 | 3.5 | 3.7 | 2.5 | 2.6 | ◎ | ◎ | ◎ | ◎ | ◎ | 30*15 | |

| D24 | 13.65 | 7.0 | 5.3 | 4.6 | 5.0 | 3.2 | 3.5 | ◎ | ◎ | ◎ | ◎ | ◎ | 35*20 | |

| D27 | 24.13 | 13.0 | 8.6 | 5.8 | 7.5 | 4.1 | 5.3 | ◎ | ◎ | ◎ | ◎ | 35*20 | ||

| D30 | 24.13 | 13.0 | 11.6 | 7.6 | 8.0 | 5.3 | 5.6 | ◎ | ◎ | ◎ | ◎ | 43*27 | ||

| D33 | 24.13 | 15.0 | 15.0 | 10.5 | 11.1 | 7.4 | 7.7 | ◎ | ◎ | 75*40 | ||||

| D36 | 30.00 | 18.0 | 15.0 | 12.7 | 13.0 | 8.3 | 8.4 | ◎ | ◎ | 75*40 |

Advantage

Significantly Longer die life

Excellent wear resistance

High surface finish

Accurately sized

High machine efficiency

Repeatability

High wire surface quality

PCD dies are frequently used for drawing:

Copper wire

Aluminum wire

Tungsten wire

Molybdenum wire

Stainless steel wire

Coated steel wire

Special alloy and high-performance alloy wire

Precious metal wire

Various other ferrous and non-ferrous metal wire types

BENEFITS

Long lasting (outlasts TC and SSCD/ND dies)

Ideal for long production runs

Ideal for highly abrasive wire materials

Wire remains round, even with significant die wear

Tailored to wire alloy

Tailored to wire requirements (quality wire surface when required)

Predictable cast & helix when required

Inventory programs available

- Hole size range

- Hole diameters: 0.030 -22.00 mm

- Applications

- Nonferrous wire, especially larger sizes where demanding wear is a problem, but surface finish is less critical.

- Typical Markets

- Aluminum wire, copper wire, stainless steel wire, tire cord, welding wire, galvanized steel wire and saw wire.

- KEY FEATURES

- Usable with dry and wet draw

- Available in any casing size

- Various grain sizes available

- Dies available for high temperature applications

- Tight-tolerance dies available

- Polycrystalline diamond can be chosen as a raw material for the following current products:

- Wire drawing dies

- Bunching, Stranding and Compacting dies

- Tubing dies

- Split dies

- Shaped wire drawing dies

- Extrusion tools (both tips and dies)

- Compacting dies

- Guide dies

- Burnishing dies