Tungsten carbide drawing dies made to your quality requirements allow you to meeting quality, uptime and speed standards. MN tungsten carbide drawing dies (TC dies) give the wire manufacturer the ability to maintain uniform wire roundness, minimizing material usage and scrap.

TC Tungsten Carbide Nib Wire Drawing Dies

BENEFITS

· Ideal for ferrous rod-size wire

· Ideal for short and trial runs

· Carbide grade tailored to wire material when required

· Special coatings available to reduce friction and/or increase durability

· Cast & helix control available

· Inventory programs available

KEY FEATURES

· Usable for dry and wet draw

· Custom case sizes available

· Various carbide grades available

· Low cost dies

· Starting from .004” (0.1 mm)

· Raw material stock available

TC dies are frequently used for drawing

· Steel wire

· Stainless steel wire

· Copper wire

· Aluminum wire

· Tungsten wire

· Various other ferrous and non-ferrous metal wire types

Tungsten carbide can be chosen as a raw material for the following products

· Wire drawing dies

· Bunching/Stranding dies

· Split dies

· Shaped wire drawing dies

· Extrusion tools

· Compacting dies

Tungsten carbide drawing dies made to your quality requirements allow you to meeting quality, uptime and speed standards. MN tungsten carbide drawing dies (TC dies) give the wire manufacturer the ability to maintain uniform wire roundness, minimizing material usage and scrap. Tungsten carbide dies are an excellent option for manufacturing ferrous rod-size wires. They are also ideal for short trial runs. MN TC drawing dies are manufactured with a mirror polish and a smooth wire entry to ensure optimal die life and string-up. MN offers a complete line of TC drawing dies for rod-size wire down to medium-size wire.

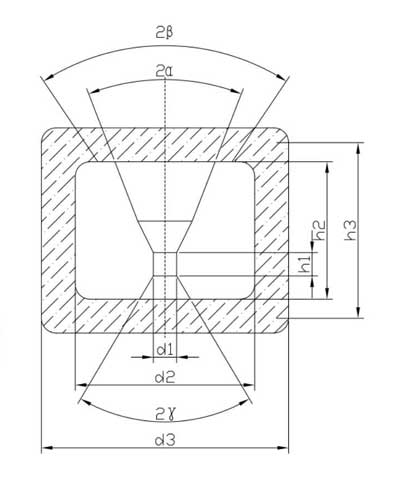

| JIS types | Nib OD d2 | Nib height h2 | Case OD d3 | Case height h3 | Reduction angle 2a | Grade Cobalt | Minimum hole size d1 | Recommended Max hole size d1 |

|---|---|---|---|---|---|---|---|---|

| W101 | 6 | 4 | 24 | 7 | 12°or16° | 6% or 8% | 0.1 | 0.6 |

| W102 | 9 | 6 | 24 | 12 | 12°or16° | 6% or 8% | 0.2 | 1 |

| W103 | 12 | 8 | 30 | 15 | 12°or16° | 8% or 12% | 0.5 | 1.6 |

| W104 | 15 | 10 | 42 | 20 | 12°or16° | 8% or 12% | 1 | 2.6 |

| W105 | 20 | 14 | 55 | 24 | 16° | 8% or 12% | 2 | 5.5 |

| W106 | 25 | 18 | 60 | 28 | 16° | 8% or 12% | 5 | 10 |

| W107 | 30 | 22 | 70 | 35 | 16° | 8% or 12% | 6 | 13 |

| W108 | 35 | 25 | 85 | 40 | 16° | 8% or 12% | 8 | 14 |

| W109 | 40 | 27 | 100 | 45 | 16° | 8% or 12% | 12 | 16 |

| W110 | 50 | 30 | 125 | 50 | 16° | 8% or 12% | 16 | 26 |

| W111 | 60 | 35 | 145 | 60 | 16° | 8% or 12% | 22 | 38 |

| W112 | 70 | 40 | 175 | 70 | 22° | 12% or 15% | 31 | 46 |

| W113 | 80 | 45 | 195 | 80 | 22° | 12% or 15% | 38 | 54 |

| W114 | 90 | 50 | 215 | 90 | 22° | 12% or 15% | 47 | 63 |

| W115 | 100 | 50 | 230 | 90 | 30° | 12% or 15% | 56 | 76 |

| W116 | 110 | 50 | 230 | 90 | 30° | 12% or 15% | 68 | 90 |

| W117 | 120 | 55 | 250 | 100 | 30° | 12% or 15% | 75 | 102 |

| W118 | 130 | 55 | 275 | 100 | 30° | 12% or 15% | 82 | 110 |

| W119 | 140 | 60 | 295 | 110 | 30° | 12% or 15% | 88 | 116 |

| W120 | 150 | 60 | 315 | 110 | 30° | 12% or 15% | 90 | 122 |

| Coating name | Coefficient of friction[-] | Micro-Hardness[Vickers] |

|---|---|---|

| C5 coating | 0.30 | 2800-3200 |

| H coating | 0.35 | 2400-3200 |

| HS coating | 0.15 | 3200-3400 |

| No coating | 0.35-0.60 | 2400 |